How 3D Scanning Is Changing Our Field Measuring Process

In my experience, the process of conducting field measures at the beginning of the project to create architectural measured drawings has been a very hands-on process. From climbing ladders, to squeezing into cobweb-filled and hard-to-reach spaces, to dealing with curious inhabitants of the space, getting accurate measurements of an entire building can feel daunting. The tools we use to complete these measurements are critical in developing the end product, which ideally is an accurate 3D model of the existing space, that then informs all design and documentation activities. 3D laser scanning is becoming an important tool in this process, and this equipment is only becoming more accessible. It is not a perfect system and has limitations like any other, but it has already had a huge impact on the processes we use to complete our initial data collecting, and on the accuracy of our resulting drawings.

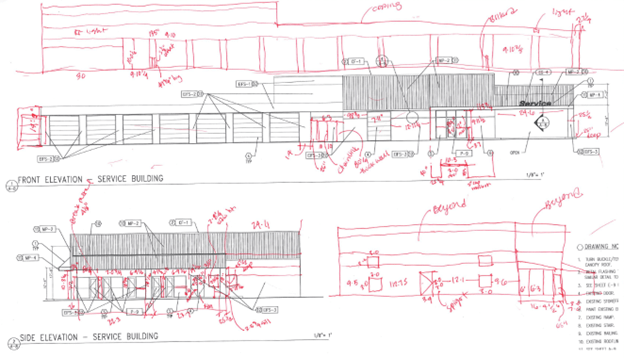

The need for a field survey of the site, with the intention of creating drawings depicting the existing conditions, comes at the beginning of a project. Many times, the existing documentation of the building will be incomplete, unavailable, or even damaged. Even when you have an original set of drawings, the building could have changed over time and the drawings are outdated. For these reasons, field measuring and verification are critical to determine the current conditions for the building before the project can begin.

Our basic documentation tools are still critical to the increasingly digital process. Before our office invested in a laser scanning camera, we used a camera and a tape measure, in combination with a laser measuring device. The accuracy and efficiency of these tools is decreased in a large or obstructed space, and they only measure linear distance. And no matter how many photos we take, there’s always that one portion of wall that is cropped from view, and might have a critical evidence of a structural column or electrical device.

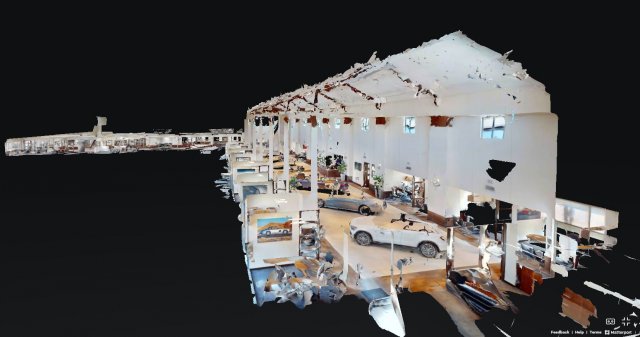

The 3D laser scanning camera is able to combine photo documentation and laser measurements into one tool. Not only does the camera take 360 degrees of photos, but it uses lasers to map the surroundings, and GPS to locate your position. This information can be accessed on your phone in real time while you are scanning, and it simultaneously creates a 3D “dollhouse” and floor plan while you scan multiple locations in the building. The scanning process is still time consuming– but the amount of information you can capture is exponential in comparison to taking measurements by hand. The information obtained can be overlaid on existing floor plans or used to create new ones, significantly enhancing accuracy and efficiency.

3D scanning has enormous potential to inform the design process in a way that the old hand method cannot. The increased accuracy and wealth of information it provides can save time and money for clients, reduce errors in drawings and construction, and enhance communication among all stakeholders. As with any tool, there are inherent limitations associated with the 3D scanning process, which is why we won’t be throwing away our tape and laser measurers any time soon. But as the technology becomes more accessible, I can only imagine that its impact on architectural documentation is set to grow even further.