Why Insulation Matters

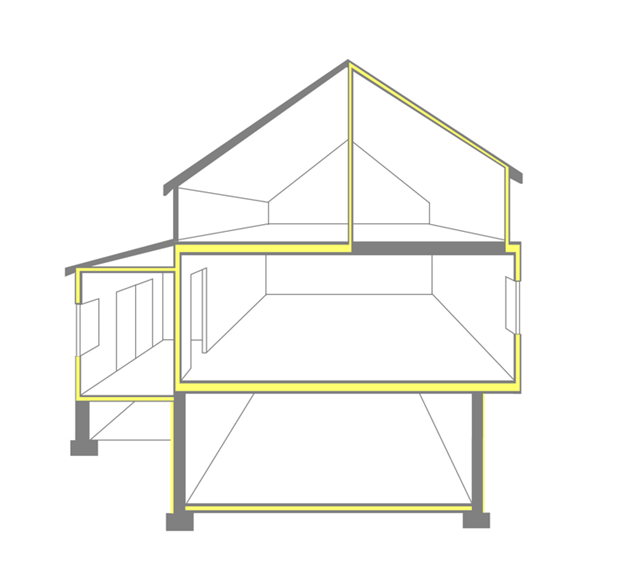

Building envelopes serve as our barrier between the ever-changing exterior climate and the mechanically-controlled environment of our interiors. This presents a challenge for architects, because while personal comfort is generally constant and narrowly defined, the outside environment can present a wide range of conditions, from day to night and from season to season. Insulation is one of the most important considerations to prevent the thermal heat transfer through the building envelope, maintaining our interior comfort while ultimately lowering the cost of heating and cooling to do so.

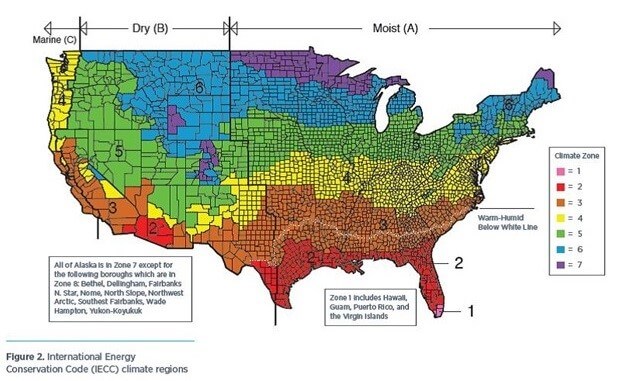

Energy Conservation Code

All states, and even some municipalities, have unique energy conservation codes that specify target insulation values for structures. Within the last two decades as demand for reduced energy use has trended skyward, regulations have also increased making it essential that every design is scrutinized for energy code compliance. The intent behind these codes is to reduce overall energy consumption by a building’s mechanical ventilation and lighting systems by specifying a base level of efficiency in the envelope. For a long-term tenant or investor, energy conservation codes will not only make the building more energy efficient, but, in turn, will save an incredible amount of money on operational energy costs.

Different types of insulation

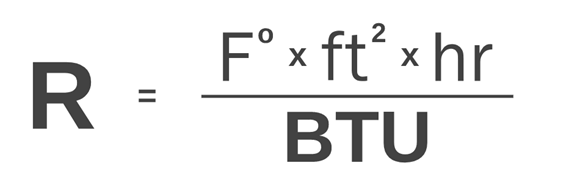

There are several types of insulation used throughout a building’s envelope, each with their own specific application. An insulative material’s ability to resist thermal transfer is specified by its R-value, with a higher R-value representing a more effective insulation. While a base material family generally has an average R-value, manufacturers’ specific product formulas will present a wide array of performance. For this blog, let’s take a look at the current options and their average expected resistive attributes.

From highest to lowest R-value per inch of thickness:

- Polyisocyanurate (thermoset plastic product): 6-7

- Extruded Polystyrene, XPS: 4-6

- Expanded Polystyrene, EPS: 4-6

- Polyurethane Foam: 6-7

- Mineral Fiber (metal stud wall): 3.5-4

How to Choose

Every project has different factors to consider when choosing an insulation, which is why relying on industry professionals is imperative. When choosing an insulation strategy there are multiple factors to keep in mind such as cost, wall thickness, insulation location, material availability, building orientation and energy codes. It’s the designer’s job to navigate the push/pull effect of all these variables to deliver a design that meets the client’s program and provides an efficient and cost-effective solution. At PRAXIS3, in addition to our in-house expertise, we utilize a program called cove.tool which allows us to analyze our designs as a whole building solution and present its performance in comparison to current cost data. This allows us to understand the implications of various insulation options on the construction budget, operational costs, and building performance. From here, we can make the right choices for each of our unique projects and ultimately provide a better service to our clients.